UK developer of rare-earth-free motors wins £23m of funding

The British electric motor developer Advanced Electric Machines (AEM) has secured £23m of new investment which it will use to scale up production, establish a global sales operation, and boost its R&D capabilities.

AEM’s motors avoid the need for rare-earth metals, thus cutting costs and the reliance on supplies of the metals from China. The motors are also designed to be recyclable with low environmental footprints.

AEM claims that its motors are more efficient than permanent magnet machines. Instead of permanent magnets or induction designs, it uses electrical steel rotors which, it says, are more sustainable to manufacture and easier to recycle, as well as being more power-dense and safer to operate.

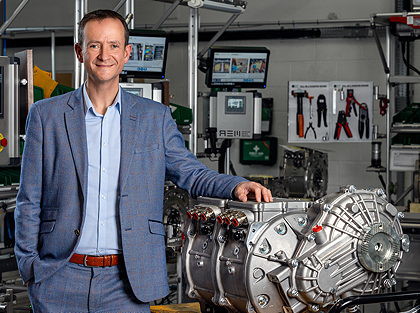

AEM was founded in 2017 as a spin-out from Newcastle University, led by CEO, Dr James Widmer, and CTO, Dr Andy Steven. The company’s vision is to design and build the world’s most sustainable motors for the automotive and transport sectors. Although AEM is developing its motors primarily for the automotive sector, they could also have applications in industry and in the railway sector.

The company’s HDSRM motor, designed for commercial vehicles, is already in production and being used in vehicles manufactured in the UK, Europe, North America and the Asia-Pacific region.

AEM's technologies are covered by 46 international patents that protect its motor designs and manufacturing processes around the world. For example, a patented high-speed rotor design delivers high torque densities and efficiencies, and can reach speeds of 30,000 rpm.

A compressed coil technology increases power densities by up to 30% by replacing copper windings with recyclable aluminium, while a single-speed, two-stage, high-reduction transmission system delivers a wide speed range, as well as low masses, high efficiencies and low noise levels. By removing copper, the motors are fully recyclable at ends of their lives, leading to less waste and greater sustainability.

AEM says its technologies will allow manufacturers of passenger and commercial EVs to reduce their environmental impacts and dependence on critical supply chains, without compromising quality or performance. Historically, engineers attempting to develop alternatives to rare-earth permanent magnet motors have struggled to match their performance. AEM claims its technology overcomes these challenges, while reducing environmental impacts.

The new Series A funding round was led by Legal & General Capital and Barclays Sustainable Impact Capital with additional investment from Par Equity. Other investors in AEM include Northstar Ventures, the Low Carbon Innovation Fund 2 and Turquoise Capital.

The new investment will allow AEM to:

• scale up production capacity at its site in Washington in North East England, creating 40 new skilled jobs over the next two years;

• establish a global sales and service operation;

• accelerate the development of its SSRD high-speed motor for passenger vehicles; and

• bolster its R&D capabilities to bring copper-free motors into production, further improving recyclability and moving AEM closer to its goal of being the world’s most sustainable motor manufacturer.

“Today’s funding announcement clears our path to sustainable growth for years to come,” says AEM’s CEO and co-founder, Prof James Widmer. “It is a vote of confidence from the market in our vision, our technical capabilities and our mission to rid EV motors of harmful and problematic materials. Everyone at AEM and our new partners are excited for the role we are now able to play in making the electric vehicle sector truly sustainable.”

Steven Poulter, head of principal structuring and investments at Barclays, adds: “AEM is solving a fundamental constraint of the EV market – the reliance on rare-earth metals for motors – which causes significant cost and supply chain challenges. By producing motors that don’t rely on these metals, AEM is able to remove the key barriers to the production and subsequent adoption of EVs. We are excited to be supporting AEM on the next stage of its journey as it expands into passenger vehicles, a growing market critical to the energy transition.”