- Home » News » Product News

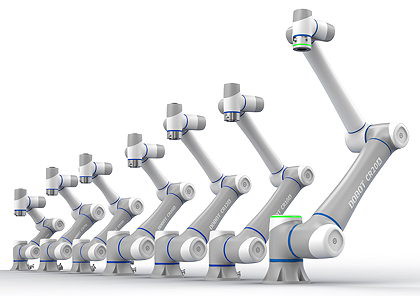

Seven-member cobot family cuts cycle times by 25%

Dobot, the Chinese collaborative robot manufacturer which claims to be the country’s biggest exporter of industrial robots, has announced a family of seven cobots with payload capacities from 3-20kg and working radii from 620–1,700mm. The CRA cobots incorporate high-performance harmonic drive reducers and electromagnetic brakes, as well as updated software and a redesigned user interface.

Dobot has also announced a smart camera (the CRV500) that uses a propietary 2.5D spatial compensation technology to allow its CRA and CR cobots to grab tilted or inclined objects accurately.

The new CRA cobots are said to improve performance, efficiency and ease-of-use. They offer:

• integrated joints with high-performance harmonic drive reducers that cut cycle times by 25%;

• optimised algorithms that reduce vibrations and achieve repeatabilities of ±0.02mm, and trajectory accuracies of 0.2–0.4mm during complex motions;

• electromagnetic brakes that auto-engage within 18ms of a power outage, limiting arm falls to less than 1mm, and preventing end-tools from dropping;

• built-in virtual boundaries, real-time payload detection and other safety functions;

• user-friendly operating software that supports graphical programming, scripting and drag-to-teach for replaying trajectories;

• multi-platform software that works with PCs, tablets, smartphones and more; and

• a control box that is 25% smaller than its predecessor, with optional IP54 protection that helps to cut maintenance costs.

The cobots support Modbus, Ethernet/IP and Profinet communications, and can connect to PLCs and other automation systems. They have 24 I/O ports and PNP/NPN switching, making expansion easy.

The 3, 5 and 10kg payload models are compatible with Dobot’s SafeSkin non-contact pre-collision detection technology which can sense obstacles within 15cm and stop an arm from moving before a collision occurs.

The 20kg-capacity model has a 1.7m working radius, and a ±0.1 mm repeatability, making it suitable for packaging and palletising applications, as well as for machining large workpieces and performing long-seam welding. Dobot claims it can halve residual vibration during high-speed stops. In palletising applications, the cobot can stack up to seven items per minute, and handle pallets up to 1,219 × 1,219mm.

A dual tool connector allows the 20kg model to support multiple end-effectors and be used with a variety of third-party accessories. This capability also avoids complex cable arrangements that can restrict robot motion.

Dobot has also developed special application software to simplify the deployment of complex processes such as screwdriving, welding and palletising. The software allows users to set up automation processes quickly without writing a line of code.

Founded in 2015, Dobot Robotics claims to have created the world's first desktop cobot. Its current six-family product line-up spans payloads from 0.5–20kg. To date, it has sold more than 68,000 cobots in 140 countries and has been China’s largest robot exporter by volume for four consecutive years.

Last year, Dobot started batch production of collaborative robots in what it says is the world’s largest cobot manufacturing plant. Construction of the 53,000m2 Shandong Rizhao factory started in 2020, and it has now produced more than 10,000 cobots.

Dobot Robotics: Twitter LinkedIn Facebook