- Home » News » Technology News

UK project uses robots to embed wiring in components

British researchers have been working on a £1.7m project to accelerate automation in the aerospace industry by using a novel robotic system to embed wiring into complex aircraft components. The venture, called Project LiveWire, has been led by Bristol-based Q5D Technologies, working in collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC). The two-year collaborative project, funded by Innovate UK as part of the ATI (Aerospace Technology Institute) programme, also involved other companies including OnePLM, M-Solv and Safran.

The aim was to automate the production of airline seating components and control systems by embedding wiring into their structures, helping cut costs and build lighter, higher-quality components.

Wiring in aircraft, cars and many consumer goods is currently done by hand, making it expensive, laborious and prone to errors which can cause failures and sometimes even fires.

The complexity and flexibility of harnesses has made automating the process difficult. For this reason, OEMs often source their harnesses from areas with skilled workforces and lower labour costs, such as Eastern Europe and central America.

However, demand is stretching the ability to supply, while pressure to improve productivity means that automating wire harness production is becoming vital to tackle challenges such as: the availability and productivity of workforces; the increasing number and variety of functions needed; the demand for mass customisation; and the uncertainty and risk from lengthy supply chains.

According to Q5D, these challenges demand a new approach. Methods such as laser direct structuring, PCB, and large-area flexible conductors offer some hope. But these methods have limited applications and cannot automate the entire production process.

Q5D has therefore developed a new approach using a robot to lay down conductive tracks or wires on complex components, thus integrating the wire harness into the product.

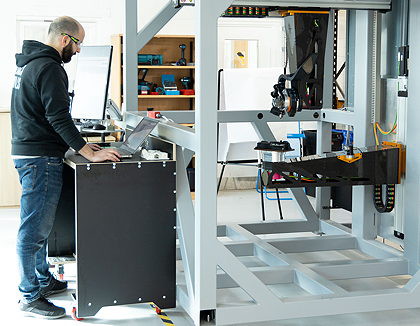

As part of the project, Q5D has created a five-axis robotic tool that can add wiring, components and printed conductive tracks to complex components. The technology could have applications from aerospace to consumer goods.

The harness manufacture and the final assembly can both be automated. Q5D says that this “revolutionary” approach could deliver significant benefits.

The company has adapted CAD/CAM principles from subtractive manufacturing and applied them to adding conductive materials to components.

Metal, ceramic or polymer parts with complex surface shapes, made using traditional methods such as casting, moulding or additive manufacturing, are loaded into the cell where polymer features, wires and components are added.

The cell can use a variety of interchangeable end-effectors to deliver different processes such as adding polymers, placing pre-made components, laying down insulated wires, embedding bare wires into polymer substrates, and creating laser-sintered conductive tracks. Designers can specify precisely where the components and conductors should be.

“Our goal is to automate the largely manual processes currently employed to make wiring harnesses with a CAD/CAM approach that will also create new product design opportunities, reduce weight, and use less space,” explains Q5D’s operations manager, Peter Todd.

As part of the project, Q5D asked researchers at the AMRC – part of the UK’s High Value Manufacturing (HVM) Catapult – to devise a proof-of-concept to calculate the position and rotation of a workpiece to allow a robot to automate the process of embedding wiring for aerospace applications, as well as to create validation processes for quality inspection.

“Q5D tasked the AMRC with making sure the position and rotation angle of the workpiece produced the best possible accuracy, while maintaining high repeatability and a fast computational process,” explains AMRC research engineer, Edwin Anarcaya Roca. “To obtain this, AMRC engineers performed a number of trials to identify the right hardware and software that would be best suited and supported the company in implementing a proof-of-concept solution using a stereo vision camera.”

Automating the robot path using a vision system will give greater flexibility to adapt to dynamic environments. Making automatic adjustments to the robot’s path on the fly will reduce the manual programming needed to re-adjust the tool path.

The AMRC has also implemented proof-of-concept computer vision systems to automate the wiring inspection. These include algorithms that can detect defects such as broken or crushed wires, stripped insulation, wires escaping from the track, and incomplete track walls.

“The techniques used in these defect detection algorithms could lead to the development of a real-time, embedded wiring defect detection system integrated with the machine itself,” says Roca. “Even though this project was looking at a pathway for use in the aerospace sector, this concept can be transferable to any robotics automation system.”

Demand for wiring harnesses is growing rapidly due to factors such as electrification, the Internet of Things and Industry 4.0. Transparency Market Research has predicted that the wire harness market will be worth $200bn by 2031.

Q5D: LinkedIn

AMRC: Twitter LinkedIn Facebook