- Home » News » Technology News

UK-developed robot arm works inside aircraft wings

A Dorset automation specialist has developed a robot arm that can perform sealing, inspection and other operations inside aircraft wings and other confined spaces. Loop Technology worked on the four-year project – funded by a grant from the UK’s ATI (Aerospace Technology Institute) – in partnership with Belfast-based Spirit AeroSystems, which led the project.

Assembly inside confined spaces such as wing boxes is a major challenge for aerospace manufacturers. These processes have traditionally been performed by hand because of the lack of automated systems with sufficient accuracy, the ability to handle relatively large payloads, and a long enough reach to replace the use of hand tools.

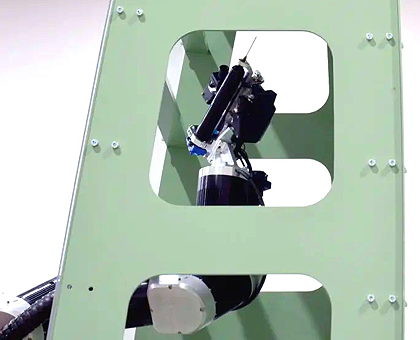

To solve this, Loop Technology has developed a seven-axis, robotically-controlled, articulated positioner called Bravura. It can be used with an industrial robot to automate sub-assembly operations including sealing and inspection inside wing boxes. Other potential uses include nut-running and swaging. The system has a reach of 1.1m and can manipulate tooling end-effectors weighing up to 5kg.

“Bravura extends the possibilities of end-of-arm tooling by adding six degrees of freedom in a compact form factor with high-torque motors, continuous rotation, and a unique path-planning solution” explains Loop’s technical director, Ross Horrigan. “Although Bravura is an articulated robot in its own right, it is typically deployed as end-of-arm tooling for a larger robot. To insert Bravura smoothly and accurately into a wing box, we use the kinematic coupling capabilities of the Bravura controller to move all 13 axes simultaneously.”

The main project, called OptiComp (Optimised Composite Wings and Aerostructures), was led by Spirit’s Belfast facility. Its aim is to ensure the UK aerospace industry can compete globally in the design, development, and production of large complex aerostructures – especially wings.

Previous attempts to automate work inside wings have used “snake-arm” robots. But these are limited by their low stiffness and restricted accuracy due to their cable-driven operation. By contrast, the Bravura positioner uses frameless servomotors, paired with high-ratio harmonic gearboxes, to achieve high power density drives that can operate with high precision.

As well as the end-of-arm positioner, Loop Technology has also developed a kit of complementary tools with vision capabilities for use in space-restricted areas.

Loop Technology: Twitter LinkedIn Facebook

Spirit Aerosystems: Twitter LinkedIn Facebook