- Home » News » Product News

Next-gen CNC system is ten times faster, and offers new drives

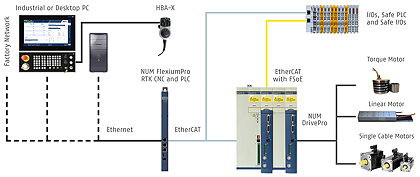

The CNC specialist NUM has launched a “radically new” CNC platform that combines CNC and PLC functions in one device, and is it claimed to set new performance benchmarks for machine control. Compared to the company’s previous Flexium+ CNC system, the new FlexiumPro platform is more than 10 times faster – from boot time and block-per-second execution, to axis control, PLC/CNC data exchange, robot and peripheral I/O interfaces. It is also said to offer significant advances in connectivity and reliability.

NUM is also launching a new series of high-performance one-, two- and four-axis drives and a new four-axis power supply. The DrivePro drives can control any type of electric motor, including spindle, servo, linear, torque, synchronous and asynchronous machines. The control loop of each axis can be closed with up to three external sensors – typically a motor encoder, a machine encoder such as a linear scale, and an accelerometer.

The new DrivePro drives incorporate a multi-core ARM processor and are implemented using advanced SoC (system-on-chip) technology. To avoid latency and overheads, there is no operating system between the CPUs and the software. Each NUM DrivePro controller can handle up to four axes simultaneously, with a position loop sampling time of 50µs, and each drive can support up to 99 parameter sets.

When equipped with the NUM-SAMX option, the drives offer the following safety functions: STO; SS1/2; SOS; SLS; SLP; SDM; SCA and SBC. The functions are activated through the system’s safe PLC using FSoE (Failsafe over EtherCat), thus avoiding the need for dedicated safety wiring.

The FlexiumPro system’s real-time kernel (RTK) combines an embedded Codesys V3 PLC with a CNC controller. Also based on a multi-core ARM processor, the RTK is implemented using advanced SoC technology. The tightly integrated technology helps to cut component counts, improving reliability and saving space. The single-board, fan-less design is 25mm wide.

The CNC system’s hard real-time operating system reduces latency and avoids the time overheads of “soft” operating systems. All aspects of the hardware and firmware are optimised to maximise machine precision and performance, while delivering secure connections.

The PLC application, part programs, machine configuration, calibration data and so on, are all saved on a removable microSD card. To secure shutdown processes, the RTK uses supercapacitors which keep the system alive for long enough to save all data in the event of a hard power-off.

Machine users and OEMs familiar with the Flexium+ CNC system will find it easy to migrate to FlexiumPro. Its PLC programming languages and environment are identical, part programs are compatible with both systems, software interfaces to custom HMIs are similar, and the EtherCat terminals and safety devices are unchanged.

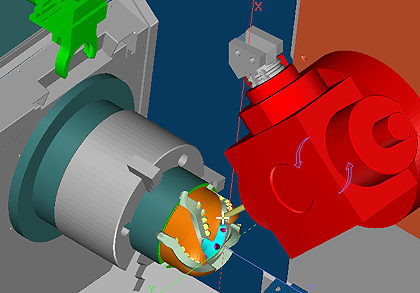

FlexiumPro retains and extends all behavioural and functional aspects of Flexium+. These include controlling up to 32 axes and/or spindles, up to 32 machining channels, and sub-nanometre interpolation. The system still supports RTCP (rotation tool centre point) and HSC (high-speed cutting) functions, as well as technology-specific functions and machining cycles.

NUM has also developed an new user interface that can incorporate OEM-defined modules with integrated functions related to their technologies. Previously, OEMs often had to develop dedicated HMIs for specific technologies in their products, which could be expensive and time-consuming.

NUM’s new FlexiumPro dual-layer HMI architecture simplifies this aspect of machine tool design. OEMs can define, modify and save the functions of the underlying user interface modules (UIMs), simplifying the creation of ergonomic application-specific HMIs.

Like the Flexium+, the FlexiumPro HMI runs under Windows. It can be connected directly to a FlexiumPro RTK or can run remotely on any PC on the same LAN as the RTK. For additional flexibility, the system also supports multi-HMI configurations for applications when a single machine tool has more than one HMI, PLC-based visualisation pages, and NUM’s Flexium 3D graphical simulation software.

NUM: Twitter LinkedIn Facebook