- Home » News » Product News

AI-based platform will predict rotating machine failures

The industrial sensing and protection company Sensata Technologies has teamed up with the Canadian-Indian machine health monitoring specialist Nanoprecise to offer a monitoring and predictive maintenance system for rotating machines that allows plant managers to detect early-stage faults and extend the working lives of their machines.

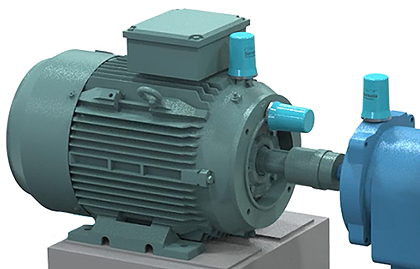

The system is based on new wireless sensors designed to be mounted on machines such as motors, pumps, blowers, fans or compressors from any manufacturer, and to monitor six variables – vibration, temperature, acoustic emissions, speed, humidity and magnetic flux. No changes are needed to the machines or their controls. Sensata says that the 6VW series IoT sensors can be set up and installed in less than five minutes using a configuration app running on mobile devices.

Using AI-driven algorithms specifically designed for rotary assets by Nanoprecise, data from the sensors is analysed at the edge for anomalies, and then sent to Sensata’s IQ cloud-based platform for further analysis and data visualisation. The platform can identify potential faults, calculate an asset’s remaining useful life, and deliver real-time alerts to plant managers via their laptops, tablets, or smartphones. The predictive maintenance capabilities can reduce the need for plant walkarounds and help managers to understand the health of their assets better.

Sunil Vedula, founder and CEO of Nanoprecise, predicts that the technology “will help change the way plant managers around the globe monitor their rotary assets”.

Naoto Mizuta, vice-president of industrial at Sensata Technologies, adds that the system “allows plant operators to gain deep machine health insights on rotary assets in a simple way. Our mission is to make asset monitoring more accessible and this solution supports that mission.”

Sensata, whose headquarters are in the US, employs more than 21,000 and has operations in 13 countries. It serves customers in the automotive, heavy vehicle and off-road, industrial and aerospace markets.

Nanoprecise specialises implementing artificial intelligence and IoT technologies for predictive asset maintenance and condition monitoring. It targets industries including manufacturing, transportation, oil and gas, utilities, mining, forestry, pulp and paper, and HVAC, offering them hardware and software that integrates physics, material science, and advanced data analytics to diagnose issues and to predict remaining useful life accurately.

Sensata Technologies: Twitter LinkedIn Facebook

Nanoprecise: LinkedIn