- Home » News » Technology News

Motor monitoring tech eliminates on-machine sensors

Schneider Electric has launched a condition-monitoring technology for rotating machines that analyses motor currents rather than relying on traditional vibration-monitoring techniques. It claims that this approach offers several advantages, including accurate prediction of imminent machine failures, the ability to operate in harsh environments, and the ability to provide data that can be used to cut energy consumption and optimise the performance of machinery.

Schneider suggests that the technology could help to avoid the 15 hours of equipment downtime that the average manufacturer experiences every week, potentially avoiding millions of pounds in losses.

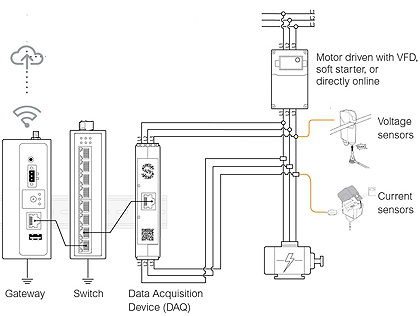

One of the biggest advantages of the technology – called MCSA (motor current signature analysis) – is that sensors do not need to be placed on the motor. They can be installed in the clean, dry environment of an MCC (motor control centre), where they are protected from dirt, moisture and wear, helping to improve reliability. Data can be uploaded to the cloud using 4G communications, further reducing the time and cost of installing MCSA sensors for an entire production line.

The system, in effect, uses the motor to act as a transducer that senses mechanical load variations and converts them into variations in current. The technology analyses waveform frequencies to indicate machine conditions, giving early warnings of any deterioration or on-load process alterations.

The sensor data is aggregated in a central, cloud-based asset management system. A set of machine-learning algorithms first model “normal” motor behaviour with an associated motor current signature. If values start to drift out of the normal range, these anomalies are detected and classified by recognising variations in the motor current signature.

Once installed in an MCC, the new technology starts a learning phase and, using expert analysis, understands the system’s frequency patterns. This process can take 2-6 weeks and allows the system to detect anomalies that develop over time.

After the testing phase has been completed, the system monitors the installation around the clock. The sensing technologies and analytical methods can be used to detect a broad range of potential failure modes for motors including stator shorts, bearing deterioration, loose rotor bars, coupling misalignments, winding degradation, mechanical or electrical imbalance and more.

If the system detects issues or potential failure modes, it can send a warning, typically weeks or even months before a failure occurs, depending on the failure mode. This allows maintenance teams to order spare parts and schedule repairs when they will have least impact on operations. MCSA failure analysis can also give clues to electrical conditions upstream of the motor that may be causing an issue.

The technology offers:

• cloud-based analytics: both known and unknown failure patterns can be predicted with a claimed accuracy of more than 90%, with minimal false positives;

• the ability to work in harsh environments: the system is installed inside control cabinets, not on the motor, eliminating the potential of malfunctions resulting from harsh environments; and

• identifying mechanical and electrical issues: as well as measuring mechanical issues, the system provides data on power functions and energy consumption, delivering energy-saving and performance-optimisation insights.

Schneider is marketing the technology as part of its EcoStruxture Asset Advisor (EEA) for Electrical Distribution and Rotating Equipment service and says it could help to reduce the 25 million electric motor failures that occur every year. The service is aimed at critical rotating equipment such as motors, compressors and pumps. Failures of such equipment results in a 5% reduction in production capacity for the average manufacturer and the resulting downtime can be extremely costly. Schneider describes the new technology as “a gamechanger” that could reduce downtime by an estimated 15 hours per week and boost productivity.

“Schneider’s new EAA will help to alleviate common electrical and mechanical failure risks that lead to unplanned downtime,” says John Flynn, Schneider’s smart factory business development manager. “Once the analysis equipment has conducted its learning phase, anomalies and warnings provide the user with crucial data which they can act on. This, therefore, allows critical machinery to be repaired or replaced before failure”.

Schneider Electric: Twitter LinkedIn Facebook