- Home » News » Technology News

Superconducting coils transmit more than 5kW contact-free

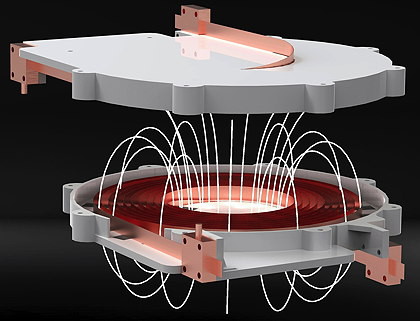

German researchers have developed a contact-free power transmission technology based on superconductors that can transmit more than 5kW of power with low losses. Potential applications include autonomous industrial robots, electric vehicles and medical equipment. The system could be used to recharge the batteries of such equipment during short idle times.

Although contactless power transmission is well-established for low-power applications such as mobile telephones and toothbrushes, previous systems for recharging in the kilowatt range have been large and heavy, because they have been based on bulky copper coils.

Now a team of researchers from the Technical University of Munich (TUM), led by two physicists, Christoph Utschick and Prof Rudolf Gross, have created a coil from superconducting wires that can transmit more than 5kW without significant losses. The work was done in partnership with Würth Elektronik and a superconductor coating specialist and TUM spin-off, Theva Dünnschichttechnik.

The researchers had to overcome a significant challenge. AC losses can occur in superconducting coils, and increase with the transmitted power. This causes the superconducting wires to heat up and lose their superconducting capabilities.

To tackle this, the researchers developed a special coil in which the windings are separated by spacers. “This trick significantly reduces AC losses in the coil,” Utschick reports. “As a result, power transmission as high as the kilowatt range is possible.”

A prototype system achieved a higher power density than is possible using commercially available systems. “The basic idea with superconducting coils is to achieve the lowest possible AC resistance within the smallest possible winding space, and thus to compensate for the reduced geometric coupling,” Utschick explains.

This researchers had to resolve a fundamental conflict. If they made the distance between the windings of the superconducting coil too small, it would be very compact but the superconducting behaviour could be lost during operation. Larger separations, on the other hand, would result in lower power densities.

“We optimised the distance between the individual windings using analytical and numerical simulations,” Utschick reports. “The separation is approximately equal to half the width of the tape conductor.”

The researchers now want to increase the amount of power that they can transmit. If they succeed, new applications could open up. For example, Utschick envisages electric racing cars that are charged dynamically on the track, as well as autonomous electric aircraft.

Wide-scale adoption of the technology still faces an obstacle, however. The superconducting coils require constant cooling with liquid nitrogen (at –196°C), and the cooling vessels used cannot be made of metal, because they could heat up in the strong magnetic fields.

“There is, as yet, no cryostat which is commercially available,” Prof Gross reports. “This will mean an extensive amount of further development effort. But the achievements up to now represent major progress for contactless power transmission at high power levels.”

TUM: Twitter LinkedIn Facebook