- Home » News » Technology News

Project marries TSN with 5G to deliver real-time comms

A consortium of organisations including Mitsubishi Electric, Ericsson and Hirschmann, is developing an end-to-end real-time industrial communications infrastructure based on 5G mobile technology and TSN (Time Sensitive Networking). The partners in the German-based 5G-Comet project want to combine TSN, which was originally developed for wired networks, with wireless 5G technology in a real-time system which provides reliable, secure communications from field-level sensors and actuators, via 5G and Ethernet connections, to an edge cloud.

The consortium says that while edge and cloud systems are gaining in importance, there is still a lack of equipment and infrastructure for integrating existing industrial machines and plants into digital IT systems.

The two-year project, funded by the German state of North Rhine-Westphalia, is being led by the Fraunhofer Institute for Production Technology (IPT), located in Aachen. Its Fraunhofer Edge Cloud is acting as the control centre for the connected systems in the 5G network and data from components in the network will converge here.

Seven sub-projects are investigating specific applications including: using 5G sensors to monitor and control complex manufacturing processes; mobile robotics and logistics; and cross-site production chains.

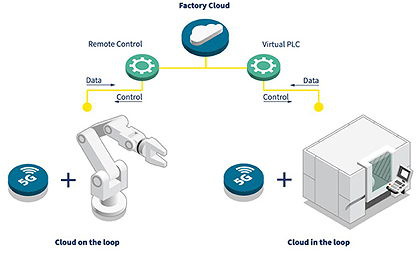

Combining the high storage and computing capacities of the cloud, the fast data transfer between 5G and Ethernet, and reliable interfaces, will allow numerous individual processes in the network to be cloud-based rather than controlled locally. In this way, specially-programmed virtual applications can be used to coordinate real process chains.

TSN, originally developed by the IEEE (Institute of Electrical and Electronics Engineers), allows high-speed data transmission with low latencies and high availability. By combining the TSN standard for Ethernet with 5G wireless communications, the project aims to provide the entire production network with a uniform communications infrastructure. The use of standardised interfaces between the mobile and wired networks should enhance the reliability of the data transmission.

The project partners are already testing a pair of applications:

• In the first, a robot with a special laser processing tool is producing complex three-dimensional surfaces with textures, engravings or markings. It requires considerable computing power to determine the exact position of the robot and the laser tool, and to control both components precisely. Low-latency data transmission via the end-to-end TSN network to the Fraunhofer Edge Cloud ensures that all of the individual systems can react quickly, without delays. The wireless 5G connection of the tool sensor technology, and outsourcing control to the Fraunhofer Edge Cloud, also allow flexible use of the laser tool.

• In the second application, robots are cooperating on an assembly task. The robot controls were previously connected directly to each other. Outsourcing the computing processes to the Fraunhofer Edge Cloud will allow calculations of robot paths to be carried out there and the results fed back to the robots. The TSN-capable network will provide consistent, reliable synchronisation and connection of the individual systems.

The 5G-Comet project is using Europe's largest 5G research infrastructure – the 5G Industry Campus Europe in Aachen which went live in May 2020 – as its test environment.

“The 5G infrastructure with the 1km2 outdoor and several indoor networks offers perfect conditions for testing and trialling time-critical use cases that place high demands on reliability, availability and latency,” explains Niels König from Fraunhofer IPT. “Communication between the respective individual systems and the Fraunhofer Edge Cloud can be extensively tested in this already existing environment.”

Other partners in the 5G-Comet project include German Edge Cloud, Isek, RWTH Aachen University, Meastream, SMS Group and Utimaco.

Fraunhofer IPT: Twitter LinkedIn Facebook

5G Industry Campus Europe: Twitter LinkedIn