- Home » News » Technology News

Levitating transport systems could be ‘a motion revolution’

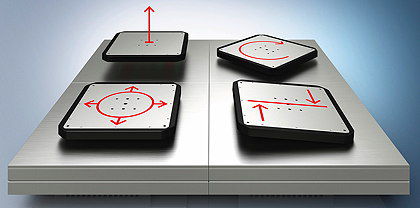

A revolution in production machinery design in which components float between workstations on magnetically levitated movers was unveiled at the recent SPS IPC Drives exhibition by two different developers. On neighbouring stands, both Beckhoff and Bosch Rexroth were demonstrating their visions of the future in which components are carried smoothly, silently and friction-free on movers that have six degrees of freedom. As well as moving freely in X and Y directions, they can rotate, move up and down by a few millimetres, and even tilt – to avoid spilling liquids, for example.

Beckhoff’s managing director, Hans Beckhoff, hailed the company’s XPlanar technology as “a motion revolution” and likened it to a “flying carpet”. The movers float above an array of planar “tiles” (each measuring 240 x 240mm) and can travel at speeds of up to 4m/s, accelerating at up to 2 g, and positioning items with a repeatability of 50µm. There are four sizes of mover, ranging from a 95 x 95mm version that can carry 0.4kg, to a 275 x 275mm version that can handle up to 6kg. The movers can be coupled together to transport heavier loads. They can even travel vertically up and down walls or be hung upside-down from ceilings.

Beckhoff’s movers can be raised or lowered by up to 5mm, tilted by up to five degrees, and rotated by up to 15 degrees (or 360 degrees if they are above a special tile). They can move freely and individually, allowing product flows to be divided or logjams to be circumvented. The contact-free technology avoids wear and contamination by friction-generated particles.

The sealed, watertight and chemical-resistant movers contain permanent magnets and are propelled by 3D travelling magnetic fields that are generated in the tiles which house flat coils and all of the electronics needed to detect and control the movers. The tiles are linked via Beckhoff’s new 1Gbit/s version of EtherCat to a PC-based controller running its TwinCat software. The controller synchronises the motion of the movers, ensuring that they do not collide. It also optimises their paths automatically and can link groups of movers to handle heavier loads.

Beckhoff believes that the scalable Xplanar technology (which is based on a system called Xbot, originally developed by a Canadian firm, Planar Motor) will open up new avenues in machine design, offering machine-builders new levels of flexibility and simplicity. For example, in some applications it could replace robots or inflexible mechanical devices.

Beckhoff sees the system being used in automated packaging, assembly, sorting and order-picking applications. It offers a choice of surfaces – easy-to-clean glass, hygienic stainless-steel, or plastic film – making it attractive for use in cleanrooms, in the pharmaceutical and food industries, and in vacuum applications.

Rexroth’s system, which does not yet have a name, has been under development for the past two years at Bosch’s corporate research centre. The patented technology can currently carry loads of up to 1.5kg, which the company plans to increase to 3kg, with a target of eventually raising the payload capacity to 20kg. The movers can travel at speeds of up to 4m/s, with a positioning accuracy claimed to be 100µm during transport, and 2µm when stopped for processing.

As well as magnets, Rexroth’s movers contain a battery-powered measurement system. They operate at a variable height of up to 20mm above the 240 x 240mm tiles, and can rotate “endlessly” through 360 degrees above any tile. Rexroth says that its system will not generate any heat, even with maximum loads and extended levitation times. Also, there are no electric or magnetic fields on the tops of the movers.

The Rexroth system is still at the development stage but the company is hoping to start pilot installations lduring 2019, before marketing the system in about two years’ time. It expects typical uses to include micro-assembly, semiconductor production, packaging and cleanroom applications.