- Home » News » Technology News

High-power, low-cost motor will ‘pack a gallon into a pint’

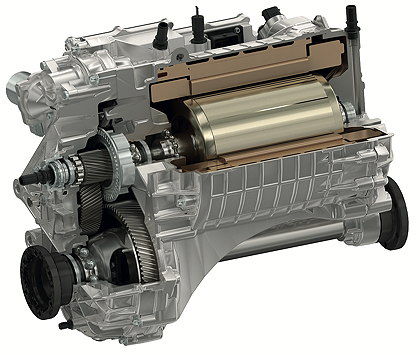

The US Department of Energy (DOE) is funding a project to develop and “auto-qualify” an electric motor, primarily aimed at next-generation electric vehicles, that will be half the cost and deliver eight times higher power density of currently available motors. The aim is to produce a motor with a peak power rating of 125kW that eliminates the need for rare-earth permanent magnets which can make up a significant portion of PM motor costs.

The developers – which include the automotive supplier and motor developer, Magna, as well as the Illinois Institute of Technology and the University of Wisconsin-Madison – say that achieving these goals would “similar to packing a gallon of milk into a pint-size container”. They are aiming to present the motor and associated technologies to the DOE for evaluation in 2021.

“Magna’s mission is to make the impossible possible by solving some of the auto industry’s most complex problems,” says the company’s chief technology officer, Swamy Kotagiri. “Reducing dependency on rare-earth magnets solves two key issues for accelerating access to electrification – supply-chain sourcing and cost.”

The project will integrate Magna’s proprietary electric motor technologies with mechanical power transmission components and inverters as part of an e-drive system. The project will include the development and use of innovative materials, cooling systems, winding technologies, simulation models, as well as control and optimisation techniques.

Another key element of the project will involving designing the technologies for low-cost manufacturing and to automotive standards, using Magna’s design framework.

Magna’s origins were as a supplier of automotive components to General Motors in the 1950s. Today, its portfolio ranges from car-seats to powertrains and complete vehicles. The company employs more than 168,000 people and has 347 manufacturing operations and 92 product development, engineering and sales centres in 28 countries. It plans to apply its powertrain, electronics and vehicle expertise to develop the new motor and drivetrain.